Services offered

We can provide a wide range of support, from data analysis to various development projects and other related areas.

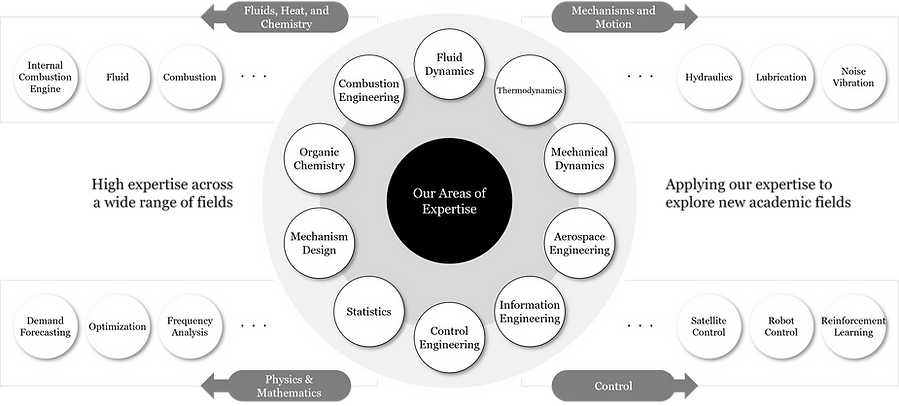

Our Expertise

We boast a high level of expertise in a variety of fields that require an understanding of complex physical and chemical phenomena.

Development case studies

We have a wealth of experience in providing support, so you can use our services with confidence.

Internal combustion engine combustion mechanism analysis - 1D model construction

Complex system optimization is required to meet various performance requirements for internal combustion engines (thermal efficiency, output, emissions, NV, etc.). Combustion development, where physical phenomena and chemical reactions are intricately intertwined, is said to be the most difficult area to predict using numerical calculations.

In particular, phenomena such as misfires and knocking have a large impact on system performance, and the ability to analyze the causes of these phenomena quickly and accurately enables efficient system development with minimal rework. We can provide a wide range of support, from mechanism analysis to performance factor analysis, analysis tool development, and 1D simulation model construction.

Applicable Areas

fluid mechanics

thermodynamics

Mechanical Dynamics

Support details

Data

analysis

Measurement and analysis support

Tool Development

Optimizing robot movements

We also support the introduction of model-based control that utilizes model information of the controlled object, and the associated parameter adjustment of the feedback controller.

We also provide motion command generation technology to realize highly accurate and efficient robot operation. Specifically, we optimize trajectories and speed profiles to suppress residual vibrations after reaching the target position while maintaining stability during operation, and to reach the specified position in the shortest possible time. We optimize control according to the characteristics of robots and actuators, contributing to improved reliability and performance in manufacturing sites and precision equipment.

Applicable Areas

Mechanical Dynamics

Control Engineering

Information Engineering

Support details

Model Building

Tool Development

Combustion chemical reaction analysis - lightweight model development

"Ignition delay," "laminar burning velocity," and "chemical equilibrium" are said to be important parameters for estimating intermediate indicators of combustion performance such as knocking, misfire, and emissions. These have nonlinear characteristics with respect to physical quantities, and require calculation of combustion chemical reactions.

General combustion phenomena are intricately intertwined with flows such as turbulence, but compared to fluid calculations, chemical reaction calculations take a much longer time, making numerical calculations difficult.

We not only calculate chemical reactions and consider mechanisms, but also build predictive models using the calculation results, contributing to reducing calculation costs.

Applicable Areas

thermodynamics

Combustion Engineering

organic chemistry

Support details

Model Building

Tool Development

Building control rules through reinforcement learning

We are working on constructing flexible controllers for nonlinear systems by applying the theory of reinforcement learning. It is possible to handle targets that were difficult to handle using conventional control theory. In the field of reinforcement learning, what is called a "policy" is positioned as a "control law" in control engineering, and this is acquired through learning.

We also have experience building controllers using inverse reinforcement learning that utilize expert control data to achieve better performance while maintaining behavior close to that of the expert.

Applicable Areas

Control Engineering

Machine Learning

Information Engineering

Support details

Data

analysis

Model Building

Tool Development

Chemical Reaction Simulation Development Service

We provide high-precision numerical analysis tools for a wide range of fields involving chemical reactions, including combustion research, engine development, catalytic processes, and materials processing.

We design and develop systems flexibly according to your requirements—GUI applications, cloud-based platforms, parallel-processing frameworks, and batch analysis workflows. Cantera serves as the core computational engine, enabling robust handling of reaction mechanisms, reaction-path analysis, pressure–temperature dependency evaluations, and large-scale parametric studies.

We develop a broad set of capabilities such as ignition delay prediction, laminar flame speed calculation, adiabatic flame temperature estimation, reciprocating engine cycle simulation, YAML mechanism file generation for Cantera, and reaction-mechanism reduction. Building on these technologies, we can extend existing features or create entirely new applications tailored to your research objectives and product-development needs.

AI-Powered Automated Document Generation

We develop software solutions that automatically extract essential information from handwritten notes, scanned files, and various document sources by combining OCR technology with advanced AI models, and then populate it into a specified document format.

These tools significantly reduce manual data entry and verification tasks, greatly improving operational efficiency and overall quality.

Our system can flexibly adapt to diverse document formats, making it highly effective for automating back-office operations and streamlining internal workflows.

Applicable Areas

thermodynamics

Combustion Engineering

organic chemistry

Applicable Areas

Machine Learning

Information Engineering

statistics

Support details

Model Building

Tool Development

Tool Development

Support details

Data

analysis

Tool Development

Flow of support

Please feel free to contact us and we will explain how we can contribute to you.

Hearing customer goals and challenges

1

Research, pre-analysis, and proposal drafting

2

To our customers

Suggestions

3

Discussion, details, and priority alignment

4

Customer

Approval and ordering

5

Work progress through regular updates.

6

final

Debriefing session

7

Business report/

Delivery of programs

8